Seamless Hastelloy C22 Nickel Alloy Steel Pipe

Seamless ASTMB622 Hastelloy C22 Nickel Alloy Steel Pipe is a cylindrical hollow component made from a corrosion-resistant nickel-chromium-molybdenum alloy, specifically designed to transport fluids or gases in highly corrosive environments. ① STANDARD: ASTM B622/ASME SB 622 for seamless ASTM B619/ASME SB 619 for welded, ...② OD RANGE : 6-457MM③ THICKNESS RANGE: 1-45 MM

Hastelloy C22 /UNS N06022/ 2.4602 Chemical Composition

|

Grade |

Ni |

Cr |

Mo |

W |

C |

Si |

Co |

Mn |

V |

P |

S |

|

C22 |

Bal |

20.00-22.50 |

12.50-14.50 |

2.50-3.50 |

≤0.015 |

≤0.080 |

≤2.50 |

≤0.50 |

≤0.35 |

≤0.02 |

≤0.02 |

Hastelloy C22 /UNS N06022/ 2.4602 Mechanical Properties

|

Grade |

Tensile Strength ksi(MPa ) |

Yield Strength (MPa) |

Elongation (%) |

|

C22 |

≥100(690) |

≥310 |

≥45 |

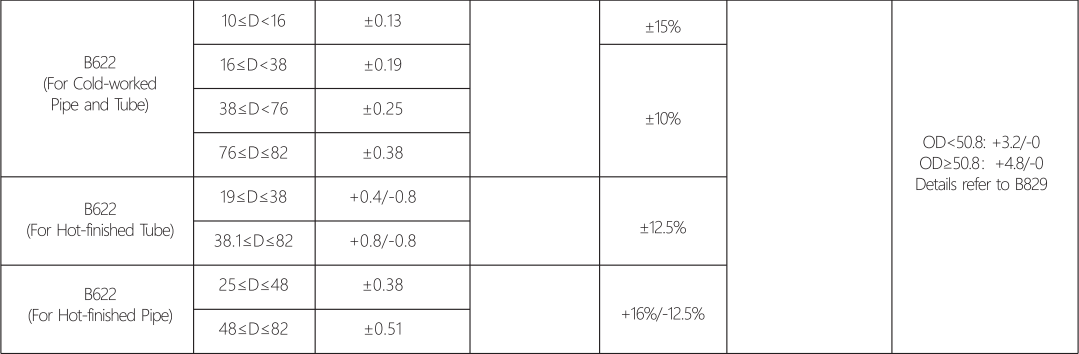

the ASTM B622 Nickel alloy seamless tube and pipe tolerance

Hastelloy C22 /UNS N06022/ 2.4602 Applications

-

- Chemical Processing:

- Hastelloy C-22 is widely used in chemical reactors, heat exchangers, and other equipment.

- Its exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking makes it suitable for aggressive chemical environments.

- Pharmaceutical Industry:

- The alloy finds applications in pharmaceutical equipment, including tanks, pipes, and valves.

- Its corrosion resistance ensures product purity and safety.

- Paper Production:

- Hastelloy C-22 is employed in paper mills due to its resistance to corrosive chemicals used in paper processing.

- It helps maintain equipment integrity and longevity.

- Oil Refining and Petrochemical Plants:

- In these industries, Hastelloy C-22 is used for components exposed to aggressive media.

- Its resistance to both reducing and oxidizing environments is crucial for maintaining operational efficiency.

- Flue Gas Equipment:

- C-22 is utilized in flue gas desulfurization systems, where it resists sulfuric acid formation.

- Its reliability ensures efficient pollution control.

- Medical Devices and Components:

- Hastelloy C-22 is suitable for medical implants and devices due to its biocompatibility.

- It is used in surgical instruments, dental tools, and other medical applications.

Remember that Hastelloy C-22’s properties make it an excellent choice for environments where corrosion resistance and durability are critical.

One of our Services--Testing

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- Raw Materials Certificate

- 100% Radiography Test Report

- 100% PMI

- Heat Treatment Charts

- Third Party Inspection Report

- Surface roughness and size measurement

- Manufacturer Test Certificate( Impact Testing, Flatten, Spin,Curve, Hardness, Intergranular ,Point corrosions, Grain size, ET,UT, HT...)

- Laboratory Test Certificate from Govt. Approved Lab

- ......

Hastelloy C22 /UNS N06022/ 2.4602 Material Summary

Nickel Alloy C22 Pipe is a fully austenitic nickel-based superalloy that's cost-effective for clients seeking ease of forming combined with superior corrosion resistance. Also known as Inconel 22 and Hastelloy C22, this material is highly ductile, making cold forming easier. Inconel 22 features resistance to an array of attacks from corrosion, pitting, crevice corrosion, intergranular, and stress corrosion cracking. Both cost effective and versatile; Inconel 22 is used by a wide variety of industries.

Nickel Alloy C-22 is a versatile Ni-Cr-Mo-W alloy with better comprehensive corrosion resistance performance than other Ni-Cr-Mo alloys, including Alloy C-276, Alloy C-4 and Alloy 625. Alloy C-22 has outstanding resistance to pitting, crevice corrosion and stress corrosion cracking. It has excellent resistance to oxidizing aqueous media including wet chlorine and mixtures containing nitric acid or oxidizing acids with chloride ions. It also offers optimum resistance to environments where reducing and oxidizing conditions are encountered in process streams.

Related Products

Seamless Incoloy 825 Nickel Alloy Steel Tube

Seamless Incoloy 825 Nickel Alloy Steel Tube is a high-performance piping product made from Incoloy 825 (a registered trademark of Special Metals Corporation), an austenitic nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium.It is a seamless pipe, meaning it's manufactured without a welded seam, providing superior structural integrity, especially under high pressure and temperature applications.The alloying elements provide broad resistance to a wide range of corrosive environments:• Chloride-Ion Stress-Corrosion Cracking: High nickel content provides excellent resistance.• Pitting and Crevice Corrosion: Enhanced by the molybdenum content.• Reducing Agents and Acids: Nickel, molybdenum, and copper provide outstanding resistance to agents like sulfuric acid and phosphoric acid.• Oxidizing Agents: Chromium confers resistance to oxidizing substances like nitric acid.• Intergranular Corrosion: The titanium addition, combined with appropriate heat treatment, stabilizes the alloy, making it resistant to intergranular attack, even after welding.① STANDARD: ASTM B163 ASTMB423 Seamless Superheater, Condenser, Hydraulic, Boiler and Heat-Exchanger Tubes② OD RANGE : 6-257 MM③ THICKNESS RANGE: 1-35 MM

Monel 400 Seamless Nickel Alloy Steel Pipe

Monel 400 Seamless Nickel Alloy Steel Pipe is a high-strength, corrosion-resistant tubing made from a nickel-copper alloy known as Monel 400. It is produced without any welded joints, ensuring superior structural integrity and leak-proof performance.① STANDARD: ASTM B165 ...② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

Inconel 718 Seamless Nickel Alloy Steel Pipe

Inconel 718 Seamless Nickel Alloy Steel Pipe are high-strength, corrosion-resistant tubes crafted from a nickel-chromium alloy known for exceptional performance in extreme environments.① STANDARD: ASTM B983...② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

Nickel 200 Seamless Nickel Alloy Steel Tube

Nickel 200 Seamless Nickel Alloy Steel Tube is high-purity nickel tube known for their excellent resistance to corrosion, strong mechanical properties, and ability to perform under extreme temperatures and harsh chemical environments. Ideal for chemical processing, power generation, and marine applications, these tubes are designed to offer long-lasting performance with minimal maintenance.① STANDARD: ASTM B161/ ASTM B163/ASME SB161/ASME AB163② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

Online Inquiry

If you have any enquiry about quotation or cooperation,please feel free to email us at admin@xtd-ss.com or use the following enquiry form. Our sales will contact you within 24 hours. Thank you for your interest in our products.