Monel 400 Seamless Nickel Alloy Steel Pipe

Monel 400 Seamless Nickel Alloy Steel Pipe is a high-strength, corrosion-resistant tubing made from a nickel-copper alloy known as Monel 400. It is produced without any welded joints, ensuring superior structural integrity and leak-proof performance.① STANDARD: ASTM B165 ...② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

Alloy400/UNSN04400/Monel 400/2.4360 Chemical Composition

|

Grade |

Cu |

Fe |

Mn |

C |

Si |

S |

Ni |

|

N04400 |

28.00-34.00 |

≤2.50 |

≤2.00 |

≤0.30 |

≤0.50 |

≤0.024 |

≥63.00 |

Alloy400/UNSN04400/Monel 400/2.4360 Mechanical Properties

|

Grade |

Condition |

Tensile Strength ksi(MPa) |

Yield Strength ksi(MPa) |

Elongation(%) |

|

N04400 |

Annealed |

≤85(585) |

≥28(195) |

≥32 |

|

N04400 |

Half-Hard |

≥85(585) |

≥55(380) |

≥12 |

|

N04400 |

Full-Hard |

≥110(760) |

≥90(620) |

≥3 |

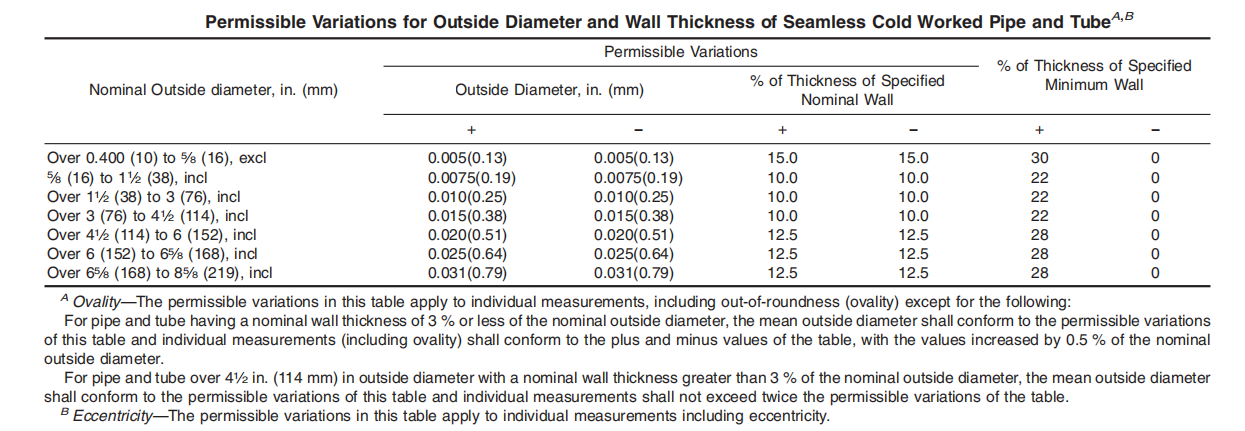

the ASTM B165 Nickel alloy seamless tube and pipe tolerance

Alloy400/UNSN04400/Monel 400/2.4360 Applications

- Feed-Water and Steam-Generator Tubing:

- Monel 400 is commonly used in feed-water and steam-generator tubing.

- Its corrosion resistance and mechanical properties make it suitable for these critical components.

- Brine Heaters and Seawater Scrubbers:

- In marine engineering, Monel 400 finds applications in brine heaters and seawater scrubbers.

- Its resistance to seawater corrosion ensures durability in harsh marine environments.

- Sulfuric Acid and Hydrofluoric Acid Alkylation Plants:

- Monel 400 is employed in chemical processing facilities, especially where it’s exposed to aggressive acids.

- Its excellent corrosion resistance makes it valuable in these applications.

- Pickling Bath Heating Coils:

- The alloy is used in pickling bath heating coils.

- Its ability to withstand corrosive environments ensures efficient operation in metal processing.

- Transfer Piping from Oil Refinery Crude Columns:

- Monel 400 is utilized in oil refineries for transfer piping from crude columns.

- Its strength and resistance to corrosion contribute to the reliability of these pipelines.

- Uranium Refining and Nuclear Fuel Production:

- Monel 400 plays a role in uranium refining and nuclear fuel production.

- Its properties ensure safety and longevity in handling radioactive materials.

- Manufacturing of Perchloroethylene and Chlorinated Plastics:

- The alloy is used in the production of chemicals like perchloroethylene and chlorinated plastics.

- Its non-toxic nature and corrosion resistance are advantageous.

- Monoethanolamine (MEA) Reboiling Tubes:

- Monel 400 is employed in MEA reboiling tubes.

- Its thermal conductivity and resistance to corrosion make it suitable for heat-transfer applications.

Remember that Monel 400’s unique combination of properties allows it to thrive in challenging environments across various industries.

One of our Services--Testing

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- Raw Materials Certificate

- 100% Radiography Test Report

- 100% PMI

- Heat Treatment Charts

- Third Party Inspection Report

- Surface roughness and size measurement

- Manufacturer Test Certificate( Impact Testing, Flatten, Spin,Curve, Hardness, Intergranular ,Point corrosions, Grain size, ET,UT, HT...)

- Laboratory Test Certificate from Govt. Approved Lab

- ......

Alloy400/UNSN04400/Monel 400/2.4360 Material Summary

monel 400 material is a nickel-copper alloy (about 67% Ni – 23% Cu) that is resistant to sea water and steam at high temperatures as well as to salt and caustic solutions. Alloy 400 is a solid solution alloy that can only be hardened by cold working. This nickel alloy exhibits characteristics like good corrosion resistance, good weldability, and high strength. A low corrosion rate in rapidly flowing brackish or seawater combined with excellent resistance to stress-corrosion cracking in most freshwaters, and its resistance to a variety of corrosive conditions led to its wide use in marine applications and other non-oxidizing chloride solutions. This nickel alloy is particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated. As would be expected from its high copper content, alloy 400 is rapidly attacked by nitric acid and ammonia systems.

Alloy 400 is a very versatile corrosion resistant material. It exhibits resistance to corrosion in many reducing environments, and it is generally more resistant than higher copper alloys to oxidizing media. Alloy 400 is one of the few materials that will withstand contact with fluorine, hydrofluoric acid, hydrogen fluoride or their derivatives. The alloy has been found to offer exceptional resistance to hydrofluoric acid in all concentrations up to the boiling point. Alloy 400 also resists sulfuric and hydrochloric acids under reducing conditions. It has outstanding resistance to neutral and alkaline salts and has been utilized for many years as a material of construction for salt plants.

Alloy 400 is one of the most widely used materials for marine applications, shipbuilding and seawater desalination plants. The alloy exhibits very low rates of corrosion in flowing sea or brackish water. However, under stagnant conditions, the alloy can encounter crevice and pitting corrosion. Alloy 400 resists stress corrosion cracking and pitting in most fresh and industrial water applications.

Related Products

Monel 400 Seamless Nickel Alloy Steel Tube

Monel 400 Seamless Tubes is a high-strength, corrosion-resistant tubing made from a nickel-copper alloy known as Monel 400. It is produced without any welded joints, ensuring superior structural integrity and leak-proof performance.① STANDARD: ASTM B165 ...② OD RANGE : 6-257 MM③ THICKNESS RANGE: 1-35 MM

Seamless Inconel 600 Nickel Alloy Pipe

Seamless Inconel 600 Nickel Alloy Pipe is a high-performance nickel-chromium alloy tube known for their excellent resistance to corrosion, oxidation, and high temperatures. ① STANDARD: ASTM B163/ASME SB163,ASTM B167 / ASME SB167....② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-65 MM

ASTMB407 Incoloy 800HT Seamless Nickel Alloy Steel Tube

ASTMB407 Incoloy 800H Seamless Nickel Alloy Steel Tube are high-performance iron-nickel-chromium alloy tubes designed for exceptional strength and superior resistance to high-temperature oxidation and corrosion. Manufactured to meet ASTM B407 standards, these seamless tubes are widely used in industries such as petrochemical, power generation, and heat treatment. ① STANDARD: ASTM B407 ...② OD RANGE : 6-257MM③ THICKNESS RANGE: 1-35 MM

UNS N08120 Seamless Nickel Alloy Steel Tube

UNS N08120 Seamless Nickel Alloy Steel Tube, also known as VDM® Alloy N08120 or Nicrofer 3725 Nb, is a nickel-chromium alloy used in industrial heating applications. Let’s explore its uses in various industries:Furnace Construction:Industrial Annealing Furnaces: UNS N08120 is commonly used in annealing furnaces where elevated temperatures are involved.Waste Incineration Plants: It finds applications in waste incinerators due to its high mechanical strength and resistance to carburization and sulfidation.Chemical Industry:In chemical processing, UNS N08120 is employed for components exposed to aggressive environments.Its resistance to carburizing and sulfiding atmospheres ensures durability in chemical plants.Environmental Protection Plants:The alloy contributes to environmental protection systems.It is used in applications where high temperatures and corrosion resistance are critical.Automotive Industry:UNS N08120 may find use in automotive components subjected to extreme heat.Its properties make it suitable for specific applications in this industry.Power Plants:In power generation facilities, UNS N08120 is utilized for superheaters, recuperators, and other high-temperature components.Its creep resistance and operating temperature range contribute to efficient power plant operation.Typical applications include furnace muffles, heat treatment baskets, wire cloth, conveyor belts, and superheaters for tubes.

Online Inquiry

If you have any enquiry about quotation or cooperation,please feel free to email us at admin@xtd-ss.com or use the following enquiry form. Our sales will contact you within 24 hours. Thank you for your interest in our products.