Seamless Inconel 625 Nickel Alloy Steel Tube

Seamless Inconel 625 Nickel Alloy Steel Tube (also known as UNS N06625 or Alloy 625) is a high-performance, nickel-chromium-molybdenum superalloy tube renowned for its exceptional strength and resistance to a wide range of corrosive environments and high temperatures.① Standards: Conforms to ASTM B444, ASTM B829, ASTM B704/B705, ASME SB444, SB704/SB705, AMS 5581, ISO 6207, VdTÜV 499, BS 3074NA21, DIN 17751.② OD RANGE : 6-257MM③ THICKNESS RANGE: 1-35 MM

Inconel625/Alloy625 Nickel/UNS NO6625/2.4856 Chemical Composition

|

Grade |

C |

Mn |

Si |

P |

S |

Cr |

Nb + Ta |

Co |

Mo |

Fe |

Al |

Ti |

Ni |

|

625 |

≤0.100 |

≤0.500 |

≤0.500 |

≤0.015 |

≤0.015 |

20.000 - 23.000 |

3.150 -4.150 |

≤1.000 |

8.000-10.000 |

≤5.000 |

≤0.400 |

≤0.400 |

Bal |

Inconel625/Alloy625 Nickel/UNS NO6625/2.4856 Mechanical Properties

|

Material |

Form and Condition |

Tensile Strength MPa |

Yield Strength (0.2% Offset) |

Elongation 4D(%) |

Hardness HB |

||

|

|

ksi |

MPa |

ksi |

MPa |

|||

|

Alloy 625 Bar |

Annealed |

≥120 |

≥827 |

≥60 |

≥414 |

≥30 |

≤ 287 HB |

|

Alloy 625 Sheet |

Annealed |

≥120 |

≥827 |

≥60 |

≥414 |

≥30 |

145-240 |

|

Alloy 625 Tube3 |

Annealed |

≥120 |

≥827 |

≥60 |

≥414 |

≥30 |

- |

|

Alloy 625 Tube4 |

Solution annealed |

≥100 |

≥690 |

≥40 |

≥276 |

||

Note:

1. Hot forming quality pipe and tubing is furnished to chemical requirements and surface inspection only. No tensile properties are required.

2. The minimum strength values apply only to tubing in straight lengths.

3. Annealed at 1600 F (871 °C) minimum.

4. Solution annealed at 2000 °F (1093 °C) minimum, with or without subsequent stabilization anneal at 1800 °F (982 °C) minimum to increase resistance to sensitization.

Inconel625/Alloy625 Nickel/UNS NO6625/2.4856 Applications

- Aerospace and Aviation:

- Inconel 625 is commonly used in aircraft engines, gas turbine components, and exhaust systems.

- Its high strength, corrosion resistance, and ability to withstand extreme temperatures make it ideal for these applications.

- Chemical Processing:

- The alloy’s resistance to corrosive environments (including acids and seawater) makes it suitable for chemical processing equipment.

- Reactors, heat exchangers, and piping systems often utilize Inconel 625.

- Nuclear Industry:

- Inconel 625 is used in nuclear reactors due to its excellent resistance to radiation-induced corrosion.

- It maintains its mechanical properties even under high neutron flux.

- Oil and Gas Industry:

- Inconel 625 is employed in downhole tools, wellhead components, and offshore platforms.

- Its resistance to sour gas (containing hydrogen sulfide) and seawater corrosion is crucial in these harsh environments.

- Marine Applications:

- Shipbuilding and marine engineering benefit from Inconel 625’s corrosion resistance.

- It is used in propeller shafts, seawater piping, and other marine components.

- Power Generation:

- Inconel 625 finds use in steam generators, boiler tubes, and heat exchangers within power plants.

- Its high creep resistance and thermal stability contribute to its reliability.

- Medical Devices:

- The alloy is employed in medical implants, such as orthopedic devices and dental instruments.

- Its biocompatibility and resistance to body fluids are advantageous.

- Automotive Industry:

- Inconel 625 is used in exhaust systems, turbochargers, and other high-temperature components.

- Its ability to withstand cyclic loading and elevated temperatures is valuable.

- Electronics and Electronics Manufacturing:

- Inconel 625 wire is used for electrical resistance heating elements.

- Its oxidation resistance ensures longevity in heating applications.

- Other Applications:

- Inconel 625 is also found in springs, bellows, and seals.

- Its weldability and formability allow for diverse engineering solutions.

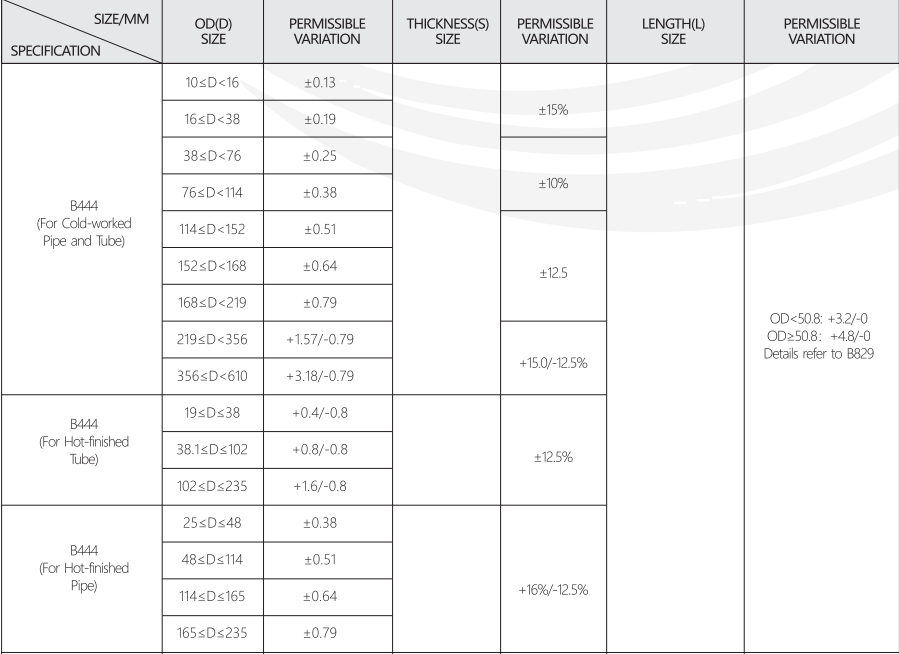

the ASTM B444 Nickel alloy seamless tube and pipe tolerance

Standard

Pipe Seamless

ASTM B444, ASTM B829, ASME SB 444

Pipe Welded

ASTM B705, ASTM B775, ASME SB 705

Tube Seamless

ASTM B444, ASME SB 444,

Tube Welded

ASTM B704, ASME SB 704

|

Pipe Seamless |

ASTM B444, ASTM B829, ASME SB 444 |

|

Pipe Welded |

ASTM B705, ASTM B775, ASME SB 705 |

|

Tube Seamless |

ASTM B444, ASME SB 444, |

|

Tube Welded |

ASTM B704, ASME SB 704 |

One of our Services--Testing

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- Raw Materials Certificate

- 100% Radiography Test Report

- 100% PMI

- Heat Treatment Charts

- Third Party Inspection Report

- Surface roughness and size measurement

- Manufacturer Test Certificate( Impact Testing, Flatten, Spin,Curve, Hardness, Intergranular ,Point corrosions, Grain size, ET,UT, HT...)

- Laboratory Test Certificate from Govt. Approved Lab

- ........

Inconel625/Alloy625 Nickel/UNS NO6625/2.4856 Material Summary

Inconel Alloy 625 (UNS designation N06625) is a nickel-based superalloy that possesses high strength properties and resistance to elevated temperatures. It also demonstrates remarkable protection against corrosion and oxidation. Its ability to withstand high stress and a wide range of temperatures, both in and out of water, as well as being able to resist corrosion while being exposed to highly acidic environments makes it a fitting choice for nuclear and marine applications.

Inconel 625 maintains its strength and stability in temperatures ranging from cryogenic to 980°C (1800°F). Its high-temperature strength makes it suitable for applications in jet engines and nuclear reactors.The alloy is highly resistant to various types of corrosion, including oxidation, carburization, and pitting. This makes it ideal for use in harsh chemical environments, including marine applications.

Inconel 625 was developed in the 1960s with the purpose of creating a material that could be used for steam-line piping. Some modifications were made to its original composition that have enabled it to be even more creep-resistant and weldable. Because of this, the uses of Inconel 625 have expanded into a wide range of industries such as the chemical processing industry, and for marine and nuclear applications to make pumps and valves and other high-pressure equipment.

Because of the metal's high Niobium (Nb) levels as well as its exposure to harsh environments and high temperatures, there was concern about the weldability of Inconel 625. Studies were therefore conducted to test the metal's weldability, tensile strength and creep resistance, and Inconel 625 was found to be an ideal choice for welding. Other well-known names for Inconel 625 are Haynes 625, Nickelvac 625, Nicrofer 6020, Altemp 625 and Chronic 625.

Related Products

UNS N08120 Seamless Nickel Alloy Steel Pipe

Seamless Inconel 600 Nickel Alloy Pipe

Seamless Inconel 600 Nickel Alloy Pipe is a high-performance nickel-chromium alloy tube known for their excellent resistance to corrosion, oxidation, and high temperatures. ① STANDARD: ASTM B163/ASME SB163,ASTM B167 / ASME SB167....② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-65 MM

Seamless Incoloy 925 Nickel Alloy Steel Pipe

Seamless Incoloy 925 Nickel Allloy Steel Pipe is a high-strength, corrosion-resistant nickel-iron-chromium alloy, enhanced with molybdenum, copper, titanium, and aluminum. Referred to as a "nickel alloy steel" in industrial contexts due to its significant iron content, this precipitation-hardenable superalloy is engineered for exceptional strength and resistance to aggressive environments, particularly in sour gas (H₂S, CO₂) and chloride-rich conditions. Seamless construction ensures structural integrity under high pressure and temperature, making it ideal for critical applications in oil and gas, marine, and chemical processing industries.① STANDARD: ASTM B983...② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

Seamless Incoloy 800 Pipe

Seamless Incoloy 800 Pipe are high-performance iron-nickel-chromium alloy tubes designed for exceptional strength and superior resistance to high-temperature oxidation and corrosion. Manufactured to meet ASTM B407 standards, these seamless tubes are widely used in industries such as petrochemical, power generation, and heat treatment. ① STANDARD: ASTM B407 ...② OD RANGE : 6-508MM③ THICKNESS RANGE: 1-45 MM

Online Inquiry

If you have any enquiry about quotation or cooperation,please feel free to email us at admin@xtd-ss.com or use the following enquiry form. Our sales will contact you within 24 hours. Thank you for your interest in our products.